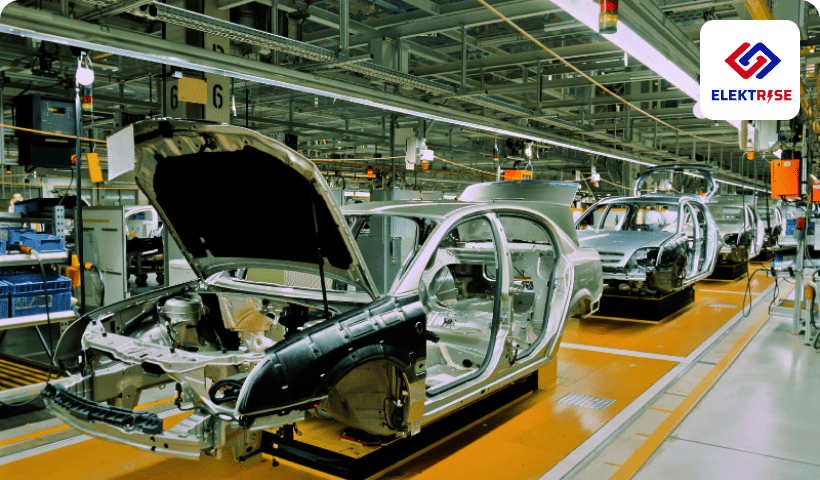

How IoT and 5G Are Shaping Automotive Technology

The car manufacturing sector is altering the major trend in…

Technology partner helping businesses innovate and drive digital transformation

We understand your business better than anybody else, thanks to our domain consultants. Together with the technology experts, these domain consultants bring in years of experience to help you navigate through your technical and business challenges.

Interwork’s exclusive product approach is the cornerstone for all software engineering services that help build and design digital products using industry standards and enterprise agility frameworks. Our product strategy and management solutions, cross-channel mobile apps, DevOps transformation, and agile practices help businesses team up with us.

Embracing digital technology has never been more critical. In an era where technology is breaking down age-old barriers, businesses must create digital experiences that are consistent and connected. Our Nexgen services will enable you to win your customers’ and employees’ loyalty and trust in an environment of digital information proliferation.

Businesses can get an integrated environment with IoT, business processes, and IT consulting. Digital solutions help increase efficiency and simplify operations. Our role as a digital solution provider is to provide customers with bespoke digital experiences that enhance customer retention and open up new business prospects. At Interwork, we deliver cutting-edge services to businesses using the latest tech.

No matter where your apps exist, whether your own servers, third-party clouds, or a mix of both, we’re your one-stop cloud service provider. We can help you upgrade and migrate your apps without a hitch. As part of our cloud services, we make it easy for you to move to the cloud of your choice and keep your apps running smoothly.

You can create an omnichannel experience by connecting all your touchpoints, devices, and channels. Interwork’s strategy and UX team use the latest technology tools to develop intuitive and specific solutions for each client. A good UX design involves collaboration and iteration. We aim to make digital experiences fun and useful for clients and users.

Interwork’s end-to-end quality assurance and testing services helps enterprises manage an increasingly complex technology landscape through various solutions. Our quality assurance practices have enabled global enterprises to gain consistency, improve productivity, lower costs, and boost profits. With the help of our quality assurance frameworks, practices, and solutions, we help our clients mitigate technical and business risks.

Interwork believes that providing the target audience with a superior product or service will positively impact them. Therefore, Interwork helps startups refine their product ideas. We use technology-driven accelerators, business models, skilled resources, standardized processes, and profound experience to help startups visualize, conceptualize and execute their business requirements, turning them into profitable ventures.

No matter how well you care for your software, technical errors, system failures, faults will always occur. When that happens, don’t let it sabotage your productivity or impact your business. Reach out to us, with Interwork’s help desk and operations support offerings, we walk that extra mile to make sure your business runs 24X7.

You need the right team and the right skill set for your project to succeed. With Interwork’s IT Staffing Services, you can hire qualified and experienced resources quickly ramp up your application development initiatives. Whether you need a prototype or a full-scale enterprise app, we’ve covered you.

Interwork’s exclusive product approach is the cornerstone for all software engineering services that help build and design digital products using industry standards and enterprise agility frameworks. Our product strategy and management solutions, cross-channel mobile apps, DevOps transformation, and agile practices help businesses team up with us.

Embracing digital technology has never been more critical. In an era where technology is breaking down age-old barriers, businesses must create digital experiences that are consistent and connected. Our Nexgen services will enable you to win your customers’ and employees’ loyalty and trust in an environment of digital information proliferation.

Businesses can get an integrated environment with IoT, business processes, and IT consulting. Digital solutions help increase efficiency and simplify operations. Our role as a digital solution provider is to provide customers with bespoke digital experiences that enhance customer retention and open up new business prospects. At Interwork, we deliver cutting-edge services to businesses using the latest tech.

No matter where your apps exist, whether your own servers, third-party clouds, or a mix of both, we’re your one-stop cloud service provider. We can help you upgrade and migrate your apps without a hitch. As part of our cloud services, we make it easy for you to move to the cloud of your choice and keep your apps running smoothly.

You can create an omnichannel experience by connecting all your touchpoints, devices, and channels. Interwork’s strategy and UX team use the latest technology tools to develop intuitive and specific solutions for each client. A good UX design involves collaboration and iteration. We aim to make digital experiences fun and useful for clients and users.

Interwork’s end-to-end quality assurance and testing services helps enterprises manage an increasingly complex technology landscape through various solutions. Our quality assurance practices have enabled global enterprises to gain consistency, improve productivity, lower costs, and boost profits. With the help of our quality assurance frameworks, practices, and solutions, we help our clients mitigate technical and business risks.

Interwork believes that providing the target audience with a superior product or service will positively impact them. Therefore, Interwork helps startups refine their product ideas. We use technology-driven accelerators, business models, skilled resources, standardized processes, and profound experience to help startups visualize, conceptualize and execute their business requirements, turning them into profitable ventures.

No matter how well you care for your software, technical errors, system failures, faults will always occur. When that happens, don’t let it sabotage your productivity or impact your business. Reach out to us, with Interwork’s help desk and operations support offerings, we walk that extra mile to make sure your business runs 24X7.

You need the right team and the right skill set for your project to succeed. With Interwork’s IT Staffing Services, you can hire qualified and experienced resources quickly ramp up your application development initiatives. Whether you need a prototype or a full-scale enterprise app, we’ve covered you.

The car manufacturing sector is altering the major trend in…

In today’s rapidly evolving business environment, staying competitive means embracing…

The transportation industry is in a time of great change,…

Businesses in the ever-evolving digital age are choosing between adapting…

Integrated Thinking and a designed oriented approach.

HOME >> Nexgen Services >> Industry 4.0

As long as you continue to reduce costs using traditional methods, you will only be able to improve efficiency marginally. The Industry 4.0 revolution transforms manufacturing and delivering goods with industrial automation and flexible factories. To remain competitive, factory and warehouse operations must embrace digitalization and the industrial internet of things (IOT).

As industrial automation has automated many processes, wireless connectivity has dramatically increased its reach, allowing factories to be automated more than ever before. Automation of industrial processes will increase productivity and performance through the use of a digital foundation.

By going wireless and cutting the cord, industries will benefit greatly. Through wireless cellular connectivity, Industry 4.0 can enhance business outcomes more than even expected by the industry. Along with this, wireless cellular connectivity allows factories to quickly switch production lines to minimize the delay in the production process.

Computers can help you run your business more efficiently by digitizing your core processes. We'll make your life easier with our speed and efficiency.

Whatever your connectivity needs, we can help and provide robust communication solutions.

Our seamless visibility is enabled by integrating sensors that track processes and record alerts and status information in real-time.

Our transparent services enable you to make quick decisions and get a clear picture, giving you purposeful insights.

Our machine learning expertise can give you future insights and predictive analysis, so you'll be prepared for anything.

With Interwork scalable solutions, you can stay ahead of the curve with the latest tools and techniques.

Make intelligent, connected products that can share their location, usage level, and health information. You can use it to improve everything from logistics to R&D to product quality to customer service. With it, you can create new, service-based business models and anticipate what the customer needs.

The manufacturing process is called smart factories or digital manufacturing when real-time data analysis, artificial intelligence, and machine learning are used. Intelligent factories are collecting and processing real-time data using sensors on equipment, giving manufacturers a 360-degree view of everything from suppliers to supply chains to equipment and manufacturing practices.

Smart assets help make the supply chain more efficient and reduce downtime. With smart assets, technicians can monitor asset performance in real-time, prevent and mitigate downtime, do predictive and dynamic maintenance, use digital twin technology, and integrate assets into business processes. With the Interwork solution suite, you can onboard assets, optimize predictive maintenance and more.

Combine IoT sensors, cameras, and machine learning algorithms to predict failures.

You can automate access control with data protection by using image processing on the device.

You can upgrade your old machines to industry 4.0 by connecting them to the network and adding sensors.

Artificial intelligence algorithms detect errors, disturbances, and unwanted stuff on the line.

When you automate routine tasks, your employees can focus on more important things.

IoT plays a crucial role in smart factories. Machines on the factory floor have sensors that have IP addresses that they can use to connect with other web-enabled devices. You can collect, analyze, and exchange data through mechanization and connectivity.

A business process management approach can help organizations align their business processes with the needs of their customers, and find out how to monitor, deploy, and measure their resources. By implementing BPM effectively, organizations can increase efficiency and productivity, reduce costs, minimize errors, and maximize results. BPM best practices contribute to a sound financial management system and provide an organization with a clear view of its achievements.

Intelligent automation can create value. With connected products, we'll be able to make better decisions about logistics and processes because we'll be able to see the whole picture. You can save money and increase production reliability by using automation in industrial applications. In general, automation is used for stuff that's hard to do by humans without getting hurt, isn't fun for them, and is easy to make mistakes in.

Cloud computing is a must in Industry 4.0. Connecting engineering, supply chain, production, sales, distribution, and service is key to intelligent manufacturing, and that's possible with the cloud. Also, cloud computing makes storing and analyzing large amounts of data more efficient and cost-effective. Cloud computing can also help small and medium-sized businesses reduce startup costs.

Manufacturing companies can harness all the information they create, not just factory floor data. AI and machine learning let you automate and predict things. Industrial machines can break down during production. Companies can boost efficiency and uptime by using machine learning algorithms to predict maintenance.

Manufacturing companies haven't always considered cybersecurity and cyber-physical systems. However, factory or field-connected equipment (OT) also opens up new entry points for malicious attacks. IT and OT equipment should be considered when going digital with Industry 4.0.

With Industry 4.0, Big Data comes from everything from factory gear to IoT devices to ERP systems to CRM systems. Real-time analytics are applied to data in supply chain management using machine learning and artificial intelligence (AI). Also, many of the technologies in Industry 4.0 are powered by big data. When you use more data, your effectiveness goes up.

We at Interwork provide scalable, sustainable, and integrated services using a holistic, industry-specific approach. Our goal is to identify growth opportunities for you based on your current state.

Everything from industrial automation to data science and IoT is available through our solutions. Our software portfolio can transform your industry and add real value.

We provide retail, distribution, service, and manufacturing clients with industry-specific solutions.

With our experienced team, we deliver solutions that meet your needs, goals, and budget.

Keeping your success in mind is our primary focus. By defining and identifying your industry's use cases, we prioritize and define them accordingly.